Making Plastic Injection Molds for Companies and Consumers

For 35 years, Quality Mold has designed and produced plastic injection molds for companies and consumers in the medical, automotive and retail industries. Plastic injection molds are designed, constructed and inspected on-site for both short and long term production runs. From quick turnaround prototyping to high cavitation tooling, our molds are always of the highest quality. Paired with expert precision — in every step — and timely deliveries, businesses who work with Quality Mold have an advantage that keeps them competitive in all markets.

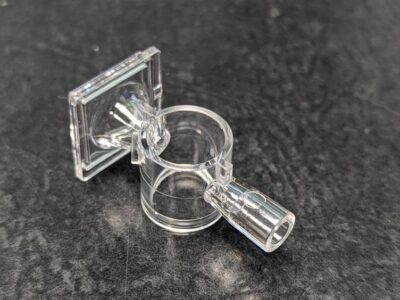

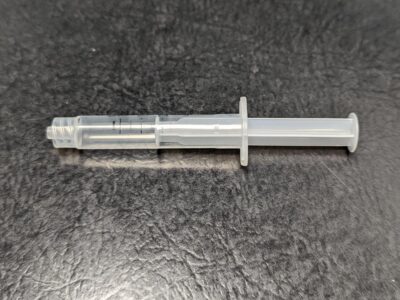

Medical

We specialize in designing and building plastic injection parts for medical equipment for health care organizations locally and across the country. Size is not an obstacle either. We have experience making molds for minuscule parts, larger pieces of machinery, and even prosthetics.

Automotive

Through the decades, Quality Mold has gained experience creating molds that yield nearly every plastic part of an automobile. Our extensive molding experience lends itself to final mold products that are made to last even longer than the automobile the molded parts will be a part of.

Consumer Goods

Whether you are a retail company looking to produce a new product or an individual searching for someone to make a mold for you to create a good independently, Quality Mold is ready to work with you. From flashlights to larger items, we have the experience to make it happen.

Products and Prototypes

Quality Mold not only builds molds but also offers the production of plastic injection prototypes for clients to test mold quality. This optional service guarantees seamless integration of the mold into the production run, with prototypes showcasing their expertise across medical, automotive, and consumer goods industries.