High-Quality Plastic Injection Molds

Inspected for Perfection

All of the plastic injection molds designed and constructed by Quality mold go through a thorough inspection process to ensure perfection in each of the molds we manufacture. What sets the plastic injection molds manufactured by this Erie-based molding company is the unparalleled quality with which they’re made.

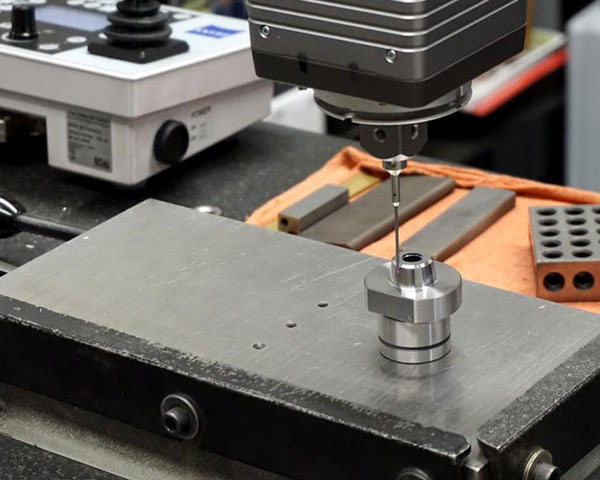

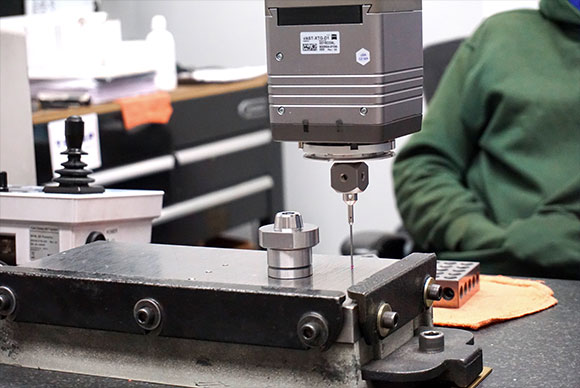

Each and every piece is inspected by hand as well as the Zeiss Contura G2, a Coordinate Measuring Machine (CMM), which uses microscopic robotic sensors to ensure the utmost precision throughout the entirety of the mold.

Quality Molds Inspected by Hand, Eye, and Robotic Probe

The Zeiss Contura G2 utilizes robotic probes to survey the inner and outer surfaces of the mold cavities. Here you can see the Zeiss in action under the supervision of the long-time inspector at Quality Mold. Setting Quality apart from other plastic injection molding facilities is the attention to detail paid by the team members, who work together as a family. This attitude covers every aspect of a production run and ensures that the work done in their Erie-based facility is always the highest quality.

Learn more about what sets Quality Mold and its products apart.

Sampling Facility

Once the mold is properly inspected in our 16,000-square-foot plant, they are sent for optional sampling at the Quality Plastics facility.

We offer optional sampling at our secondary Erie, PA location. With this, we can give yet another level of assurance that your mold will function properly and produce the best quality products.